| UD Technologies are manufacturers of Digital vacuum controller for Plant and Laboratory Level . |

| The article says about how to minimize solvent losses using Vacuum Controller . Batch distillation and subsequent condensation of vapors get maximum recovery is very common in API, Pharmaceutical intermediate and Fine Chemicals Industry. |

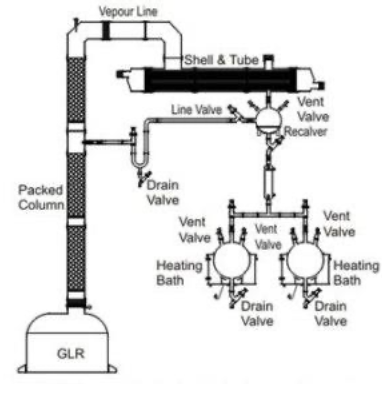

Generally, it has set up of

| • Reactor |

| • Vapor pipe/Fractionating column • Reflux line • Overhead condenser –Primary and secondary where generally Cooling water and chilled water as utility • Receiver • Vacuum Source |

In certain cases; There is only reflux and Evaporation and condensation of solvent vapors (Not distillation)In some cases there is fractional distillation to remove high boilers, in some case, Gases like HCL and SO2 also evolve. With them, solvent vapors also rise. In API and Pharma Intermediate industry, Plant is designed for Multi-Product. It means that the same set up shall be used for More than one product and uses different organic solvents. In this scenario, Utility and vacuum source is fixed. There are series of such reactors where batch distillation requires and runs at the same time. Solvents used are low Boiling points to High Boiling Point –Methylene chloride to Toluene. Even at the plant design stage; the designer does not know that which new product (Other than Defined products) may come and which solvents might be used. So Vacuum source majorly may tripe effect steam ejector for a very high vacuum. However Different stages can be used for different vacuum depending on available vacuum.

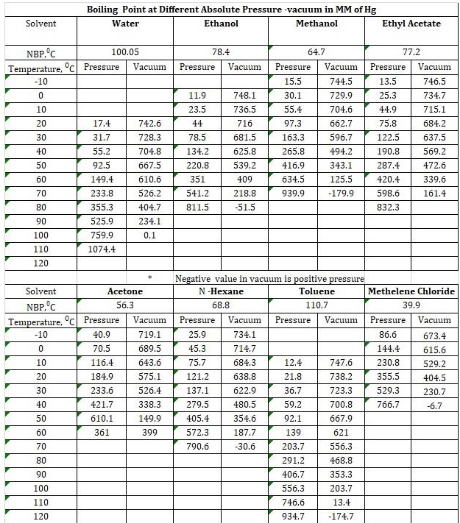

Now, what happens in reality and how solvent losses happen. To have a real case; we presume with the utility of Cooling water(28 Deg C to 33 Deg C) and chilled water(8 Deg C- 11 Deg C) with Full vacuum (say 750MM Hg). Thumb rule for efficient condensation is that boiling point shall be at least 25-30 deg higher than Coolant outlet temperature. Please note that I used the word ‘efficient’ not; 100% Condensation. Please find the table of different boiling points at different absolute pressure and vacuum for different pure solvents. Values of Absolute pressures taken by calculation Vacuum values arrived by deducting absolute pressure from 760. So Negative vacuum values are positive pressure. We shall now take the case of toluene and ethyl acetate at 30 deg c (which is 20 deg c higher than chilled water Outlet temperature) and vacuum of 725 mm Hg. At 30 deg c boiling point, vacuum required for Toluene and Ethyl Acetate is 723.3 MM and 637.5 MM Hg. Data shows that toluene shall condense at this vacuum, but Ethyl acetate shall not condense efficiently at 725 MM Hg as the boiling point of Ethyl acetate shall be between 5-8 deg c at this vacuum. So ethyl acetate escapes from the condenser to vacuum source We have considered this example at 725MM Hg for Pure solvent. For Evaporation in solution at this vacuum, the boiling point is higher so that you can observe Evaporation. Batch distillation occurs in boiling range. It means that during initial distillation; Solvents may be in appreciable quantities in solution so boiling point shall be nearer to the boiling point of the pure solvent. So losses are higher at the initial stage and solvent recovery at end of Batch distillation.

I take one real example for a better explanation. At one Batch distillation set up, the Distillation of organic solvents occurs at atmospheric pressure. To have quick condensation, vacuum applied and found that there is little condensation and faced heavy solvent losses. What happens that after applying vacuum, boiling point lowered and reaches nearer to outlet temperature of Coolant. These type of cases happens in continuous distillation or evaporation. Further, When solvents condensed on the shell side of Shell and tube heat exchanger, the Exit temperature of the Condensed solvent is nearby by boiling point. If sub-cooler with lower temperature(than Vapor condenser Coolant) is not used; Solvent may again vaporize in Receiver(Vacuum is applied at Receiver to collect solvents). So, Solvent loss continues. For Chemical Industries; there is constant pressure to reduce Raw material cost. In such cases, solvent losses increase raw material Cost So, How to think Green?

How to minimize Solvent losses and stop money loss and reduce solvent inventory?

How efficient condensation can be set for the Multi product plant?

| One solution is More Cold Coolant shall be used considering the boiling point at available vacuum which increases Fixed capital cost and working capital cost. Many times it is not possible to use this solution in existing plant The proper solution for efficient condensation is to apply an appropriate vacuum so that Cooling water has maximum condensation and chilled water shall cut down other vapor pressure. More precisely Vacuum to be selected such that boiling point shall be 25-30 deg Higher than Outlet temperature of the coolant. |

| For this, vacuum controllers are to be used between vacuum source and receiver so that required vacuum can be applied for Batch distillation/Continuous evaporation or distillation One other case, I would like to discuss that in batch Distillation, there is a case where the product to be distilled has high boiling point and In Mixture, there is a low boiling point solvent. This is to be removed in the finished product to have better purity. The appropriate vacuum should apply to remove low boiling point solvent initially and then apply higher vacuum to distill high boiling point Product to get better purity product Some Batch distillation can be converted to continuous distillation. Automatic/Semi-Automatic Vacuum Controller is available which is to be used in between vacuum source and System to be evacuated. Solvent losses in Batch distillation shall provide a controlled vacuum to System to get efficient condensation and results in better recovery. The Vacuum controller can be customized according to Process steps or process requirements. |

| Vacuum controller are more useful for continuous distillation. The material of construction for the vacuum controller shall be chosen according to process requirements Please visit https://udtechnologies.com for more details & order |