Functional Safety Engineer, TÜV Rheinland ID-No. 4274/11 Machiner

Many machines pose hazards to the operator while trying to clear jams, setting up, or other operational aspects that requires interaction. There are many safe drive monitoring features that can be applied to make the operation safer, with safe speed monitoring and standstill monitoring the most prevalent. These are used not only during the normal automatic operation of the machine but also during manual operation of the machine to lower the risk and keep the operator safe.

Safe Operational Speeds

Sometimes machines may need to be operated outside of normal conditions, at various speeds and with safety guards open. These occasions would include set-up and parameter setting tasks. European harmonized C-standards, such as DIN EN 12417, have defined several machine operating modes:

Mode 1: “Automatic” – a machine engaged at its normal production process speed with all safety guards closed and secured.

Mode 2: “Set-up” – the machine is running at significantly reduced speeds with the safety guards opened to allow for adjustment activities.

Mode 3: “Extended manual intervention” – requires the use of an enabling switch to allow operators to activate a limited number of machine functions at higher speeds, with safety guards open. Maximum speed is prescribed to set limits.

Standstill

Another consideration in the monitoring of safe speeds is to insure that the machine has reached standstill before safety guards can be opened. After the removal of power to a motor, a machine may still pose hazardous conditions because of flywheel overrun, spindle momentum, or unstable rest positions. Guards protecting these areas need to remain locked until dangerous conditions have abated.

Methods of monitoring speed or standstill

There are several methods of monitoring safe speeds and standstill:

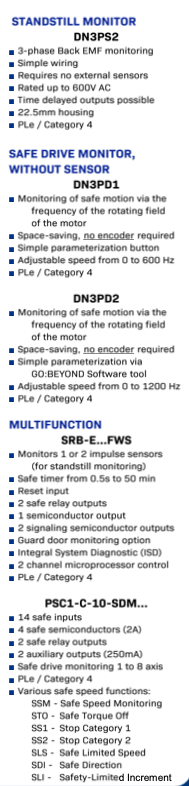

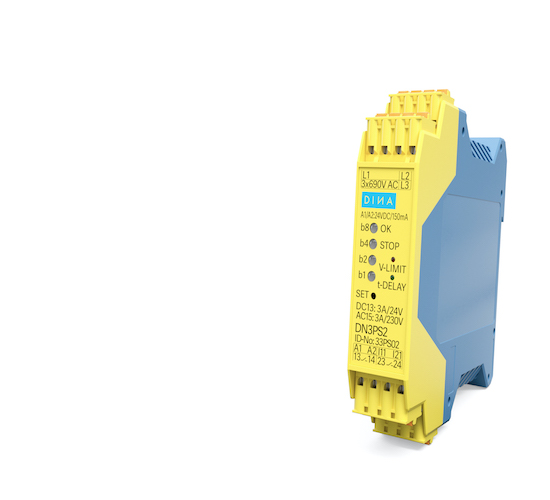

Back EMF monitoring

Back electromotive force, or Back EMF, is a phenomenon that occurs in electric motors where the rotating armature in the presence of a magnetic field produces a voltage which opposes the original applied voltage. Since Back EMF is proportional to the armature rotational speed and remains after the supply voltage has been removed, monitors can use it to indirectly measure the motor’s speed or determine standstill if absent. The DN3PS2 standstill monitoring relay uses this method.

Safe motion monitoring via frequency

Safe speed is determined by monitoring the frequency of the rotating field of the motor. This unique method is cost effective because it does not require sensors and has minimal setup. DN3PD1 and DN3PD2 safe drive monitors use this method.

Monitoring sensor signals

There are a variety of devices that can generate a signal based on the movement of the machine, such as proximity sensors, resolvers, and encoders. The signals generated are picked up by the monitor to determine speed or standstill. The SRB-E…FWS Series uses proximity sensors to monitor standstill while the PSC1 can use various types of encoders to monitor multiple axis.

Fail to safe timer

Another method to insure standstill is to incorporate a fail-to-safe timer in the circuit. Once power is removed from a motor running at a specific speed, it will usually reach standstill in a consistent amount of time. The timer can be set to delay the enabling signal to unlock the guard doors for the duration needed for the motion to stop. The SRB-E…FWS Series can be used to safely unlock guards at a consistent defined time.

SCHMERSAL INDIA PVT LTD Plot No – G-7/1, Ranjangaon MIDC, Tal. – Shirur, Dist. – Pune 412 220. +91-9607800255 | SWankhede@schmersal.com

LOGIN

LOGIN

DAFTAR

DAFTAR

WA

WA

LIVECHAT

LIVECHAT