Mr. Nanda Kishore Pamidi | Director

Fanfire Solutions

Electricity has become the fourth fundamental necessity after Roti, Kapada & Makan. Despite this necessity we achieved 100% electrification only recently after decades of independence. India has a unique feature of cross subsidy as a policy, which allows government to charge industries more, and to subsidise agriculture and lower income groups.

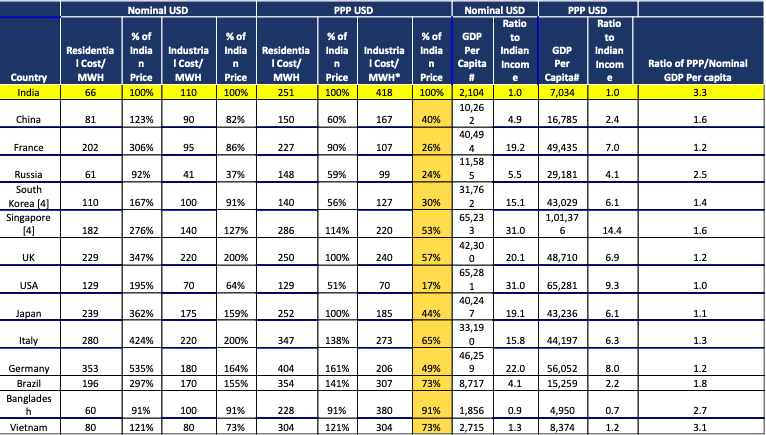

As a consequence of this Indian industry pays the highest price for the electrical energy on a PPP basis , even more than most of the developed economies Below tables provides a summary of the price comparison among various countries. The table also provides data of prices in different countries as a % of what Indian Industry Pays.

* PPP arrived using same ratio of Residential cost as per IEA

Chinese industry pays 40%, French Industry pays 26%, USA Pays 17%, Japan pays 44%, Korea pays 30% of Indian Industry price, making Indian industry less competitive.

Competitive Electricity pricing will enable Indian industry to scale in manufacturing and can be an alternate manufacturing hub.

Despite paying the highest price, 24/7 Quality power supply without interruption is still a pipe dream for Industry in India. The reason being an inefficient distribution system which is mostly manual thus leading to a lot of technical faults besides unplanned load shedding.

Indian Industry need to urgently implement Energy Conservation measures, whereas Government need to urgently reform the Power sector, to become #AtmaNirbhar

Recent Reform bill introduced by the Ministry of Power is a step in the right direction, but we need to do more, sooner. Cooperative federalism should not lead to Cooperative Inefficiency.

However the Industry cannot wait for the government reforms to come into effect since it may take a while for the reforms to reach the ground

In view of this Indian Industry has the highest need to implement Energy efficiency measures primarily to bring down the cost of Energy in operations

The following 6 step approach could immediately help Industry in reducing their cost of electrical energy:

- Identify the Energy Guzzlers

- 20% of the loads by number consume 80% of the energy. Just by making a list of all connected loads will give the picture of the energy consuming loads

- Measure the existing energy consumption and make a base line

- Perform an energy audit either inhouse or through external consultant and measure the energy consumed by these energy guzzlers

- Perform the study with respect to time of the day and record the instantaneous load and energy consumed

- Analyse the energy consumption and verify if the energy consumed is in line with the Name plate values or Specified values of the supplier

- If it’s not inline, perform a root cause analysis with the help of the supplier if there is any abnormality in the machine. If its inline move to next step

- If you do not have an APFC panel, we suggest you have once since most of the utilities are billing on KVAH and having APFC panel saves the cost

- Divide the Loads into categories

- Once you made a baseline consumption of the loads, Categorize them into Critical (non-negotiable), important (Negotiable), non-critical loads. Don’t try to fit every load into Critical as this follows a distribution curve

- Apply Peak Shaving method for Demand side management

- Try to move the non-critical loads into Non peak hours as much as possible, and important loads as necessary between non peak and peak hours

Since usage of energy in non-peak hours gives an incentive in the form of reduced price from utility

- Use DG backup for Short Peak demand in factory

- Most of the utilities charge a fixed price per KVA of maximum demand or 75~85% of the contract demand whichever is higher, subject to not exceeding the contract demand. If you exceed the contract demand the penalties may be huge varying from 1.2X to 6.5X of the fixed cost depending on the category of the customer. Some utilities record the maximum demand even for as short as 15 minutes in a whole month.

- By analysing the load demand every minute using an automatic recorder, you will get an idea of the how much is the Maximum demand recorded and for how long

- For maximum demands exceeding the contract demand, you can use backup DG to supply the extra demand which may be few hours in the whole months (depending the analysis in above step), thus saving the penalty costs

- In case of non availability of DG back up, and your maximum demand is consistently exceeding the contact demand, then the contract demand can be enhanced from utility (However remember higher contract demand leads to higher fixed costs)

- Use Harmonic filter to reduce the distortion power factor thus reducing the KVAH demand

- There are two kinds of power factor Displacement power factor and Distortion power factor. Displacement PF is caused by Inductors and capacitors where as Distortion PF is caused by VFD’s, Semiconductor based devices, Electronic loads etc

- Harmonics cause extra energy losses in Motors, Transformers thus leading to overheating and premature failure. Harmonics introduce a distortion in the waveform which is a deviation from Pure sine wave thus introducing the distortion power factor. Effective Power factor = Displacement PF * Distortion PF thus reducing the real energy output for the KVA drawn

- Use a set of adjustable passive filters, a low cost version or a dynamic real-time adjustable active filter to correct the distortion power factor

Step 1-4 may need a very low investment in measuring meters and some manhours of effort of maintenance teams and some modification in panels for Step 5.

Only in cases of full levels of automation would require investments in steps 4 & 5.

Step 6 need to be done only in few cases where the equipment are critical and Industry wants to set a global target in efficiency and improve brand image

In today India with the advent of Start-ups there are plenty of IoT based options available that are low cost and fast and easily deployable to achieve the steps from 1-5

India is at an inflection point in History and COVID provides the best opportunity for visibility to India be its Ayurvedic culture, or our lifestyle that has one of the lowest mortality rates . The world is going to watch & learn from India and its ancient practices

In view of this setting ourselves the energy efficiency target we can be globally competitive will only enhance the global image thus increasing our exports as additional benefits